Precision. Protection. Performance.

Our Electroless Nickel Finish is built around your needs!

Metal Finishing Done Right!

(814) 453-7531

Finish Name

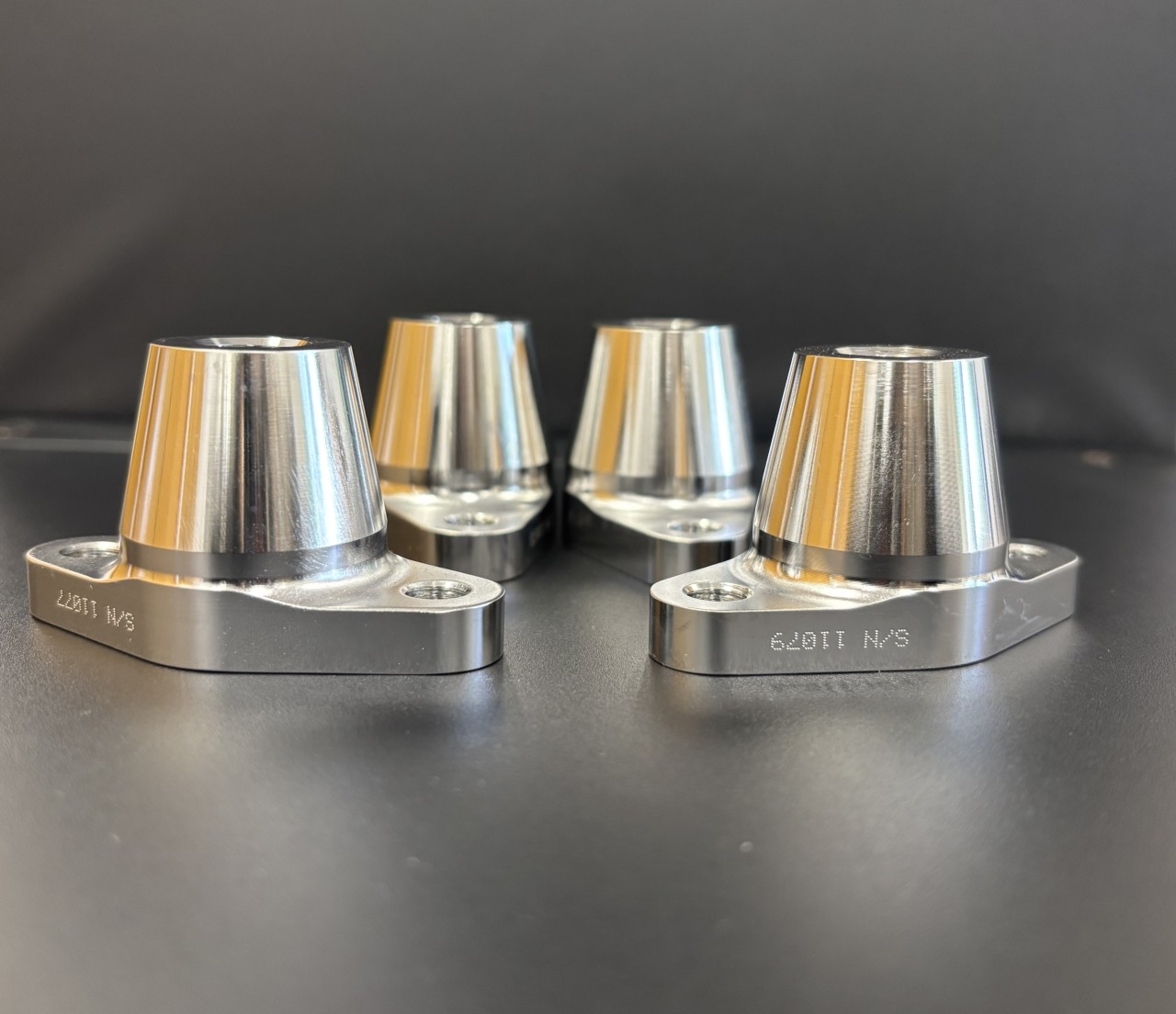

Electroless Nickel Plating

Specialty Electroless Nickel Plating

Specification

AMS-2404

AMS-C-26074

ASTM-B-733

Industry use

- Aerospace

- Military and Defense

- Automotive

- Electronics

- Industrial

- Oil and Gas

- Plumbing

Base metal substrate

- Aluminum die-substrate

- Brass

- Steel

- Stainless steel

Effect

Mid phos 6-9%

Low friction

Bright

Anti-corrosion

Electrical conductivity

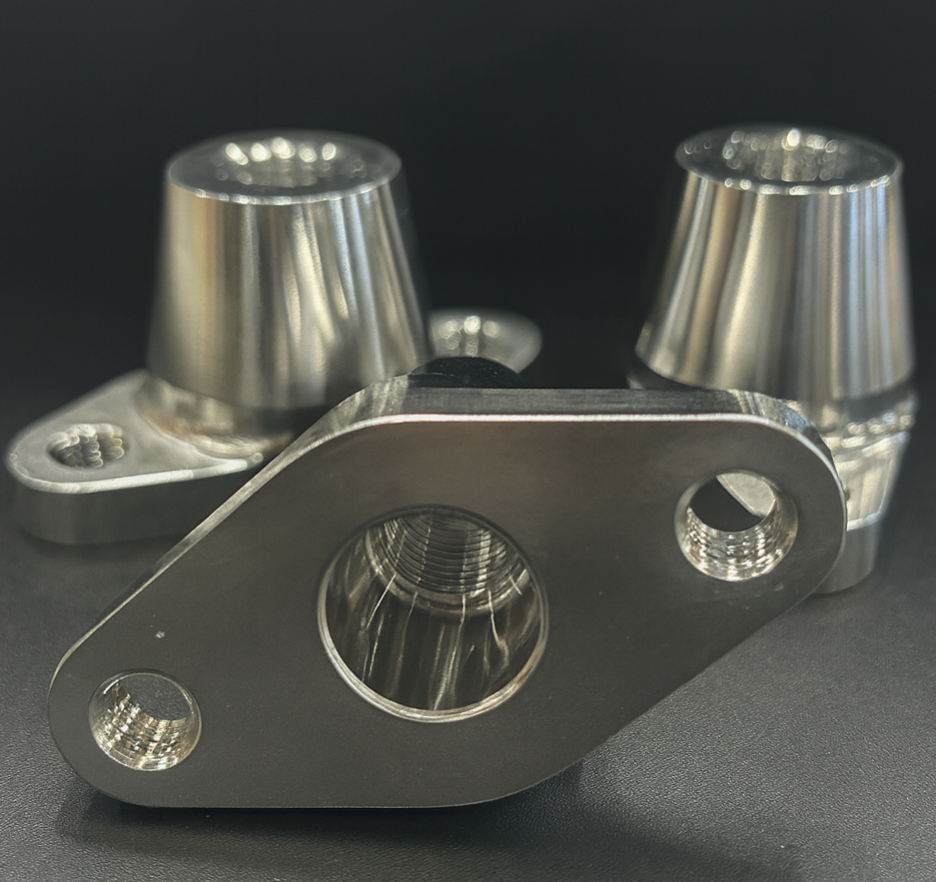

Uniform nickel coverage on interior

Suitable for

Fasteners

Specialty Fasteners

High End Fasteners

Electronic Fasteners

Regulator small parts

Valve small parts

Benefit

Electroless nickel plating is used to provide protection from wear and abrasion, resistance against corrosion, and add hardness to parts of all conditions. Each nickel phosphorus alloy coating has particular advantages depending on the application and type of nickel alloy used in the process.

Let's bring Your Project to Life - Free Quote

Electroless Nickel Plating

Electroless nickel finishes cover a wide variety of nickel phosphorus alloy coating. The phosphorus content in electroless nickel coatings can range from 2% to 13%. Erie Plating specializes in mid phosphorus with a phosphorus content 5% - 9%. For customers, Erie Plating welcomes your inquiry and will be happy to work with you to provide a finish that meets your needs. Each type of electroless nickel has particular advantages depending on the application and type of nickel alloy.

Medium phosphorus electroless nickel (available)

- Very bright and semi-bright options

- High speed deposit rate

- Very stable

- The most common type of electroless nickel applied