Electropolishing-Nadcap

Finish name

Electropolishing, Nadcap

Electrochemical polishing, Nadcap

Anodic or Electrolytic polishing, Nadcap

Specification

ASTM-B912

Base metal substrate

Stainless Steel Alloys

Accreditations

Nadcap

Benefit

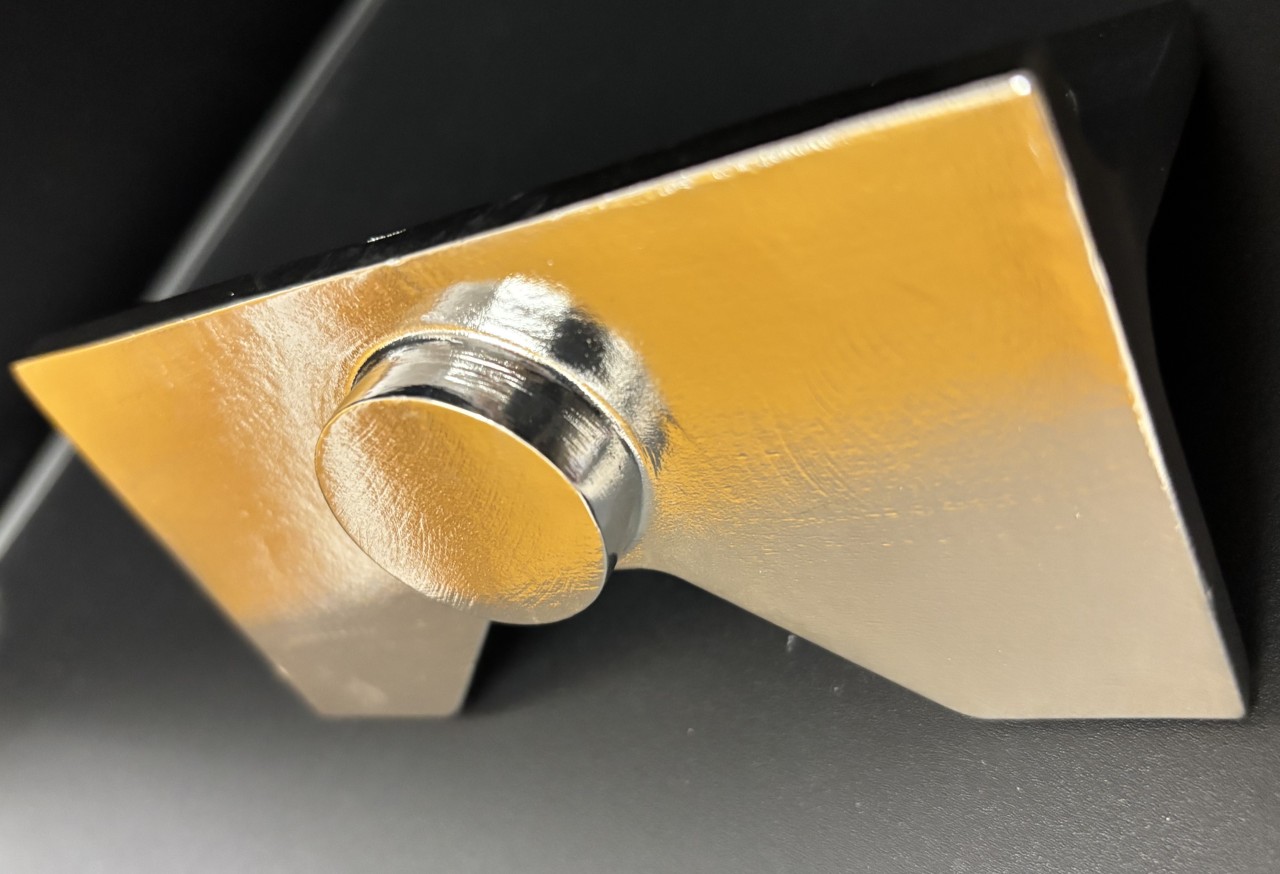

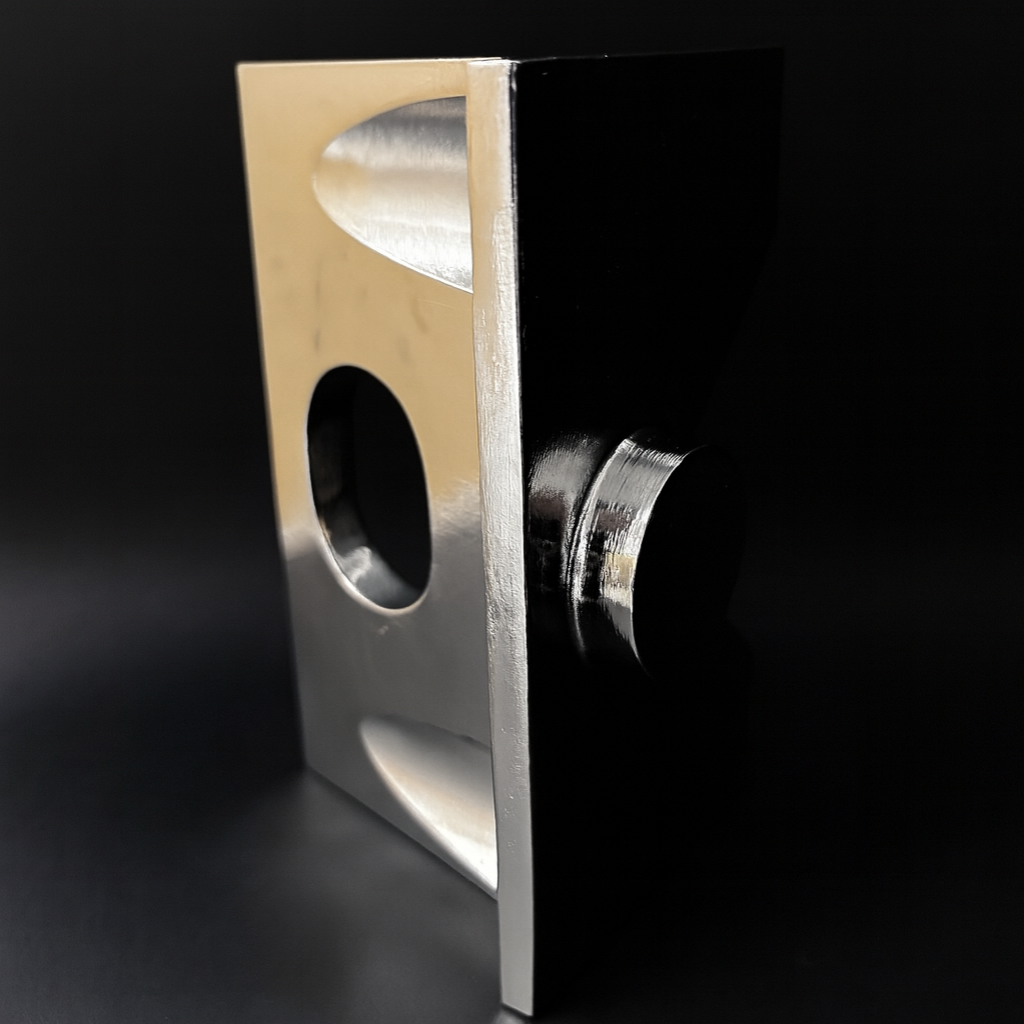

Electropolishing uses current flow in a chemical bath to smooth a metal surface by removing surface material.

It reduces the surface roughness by preferentially eroding micro-peaks.

It is used to passivate (make the surface less reactive), and deburr metal parts.

The end result is a very clean and smooth finish.

Let's Bring Your Project to Life - Free Quote

WHY CHOOSE US FOR YOUR ELECTROPLOSIHING NEEDS?

At Erie Plating Company, we deliver precision electropolishing services that meet the highest standards.

Our Nadcap accredited process ensures consistent, high-quality results with superior surface finish, enhanced corrosion resistance, and improved metal performance.

Whether you require stainless steel brightening, micro-deburring or biocompatible surface preparation, our team has the expertise and certification to meet your most demanding specification.

NADCAP Accredited - Trusted by Aerospace, Defense and Medical industries.

Choose reliability, certification, and excellence-choose Erie Plating Company for your electropolishing needs.