Passivation, nitric and citric - Nadcap

Finish name

Passivation, nitric and citric, Nadcap

Stainless steel Passivation, Nadcap

Specialty Passivation finishing on Stainless Steel, Nadcap

Stainless Steel, Nadcap

Citric RoHS Passivation, Nadcap

Specification

AMS-QQ-P-35

AMS-2700

QQ-P-35

ASTM-A380

ASTM-A967

Industry use

- Aerospace

- Medical

- Automotive

- Military and Defense

- Computer

- Electronics

Base metal substrate

Stainless Steel

Various Stainless Steel Alloys

Effect

Corrosion resistance

Stainless Steel passive after cleaning

Special cleaning of stainless surfaces

Accreditations

Nadcap

Suitable for

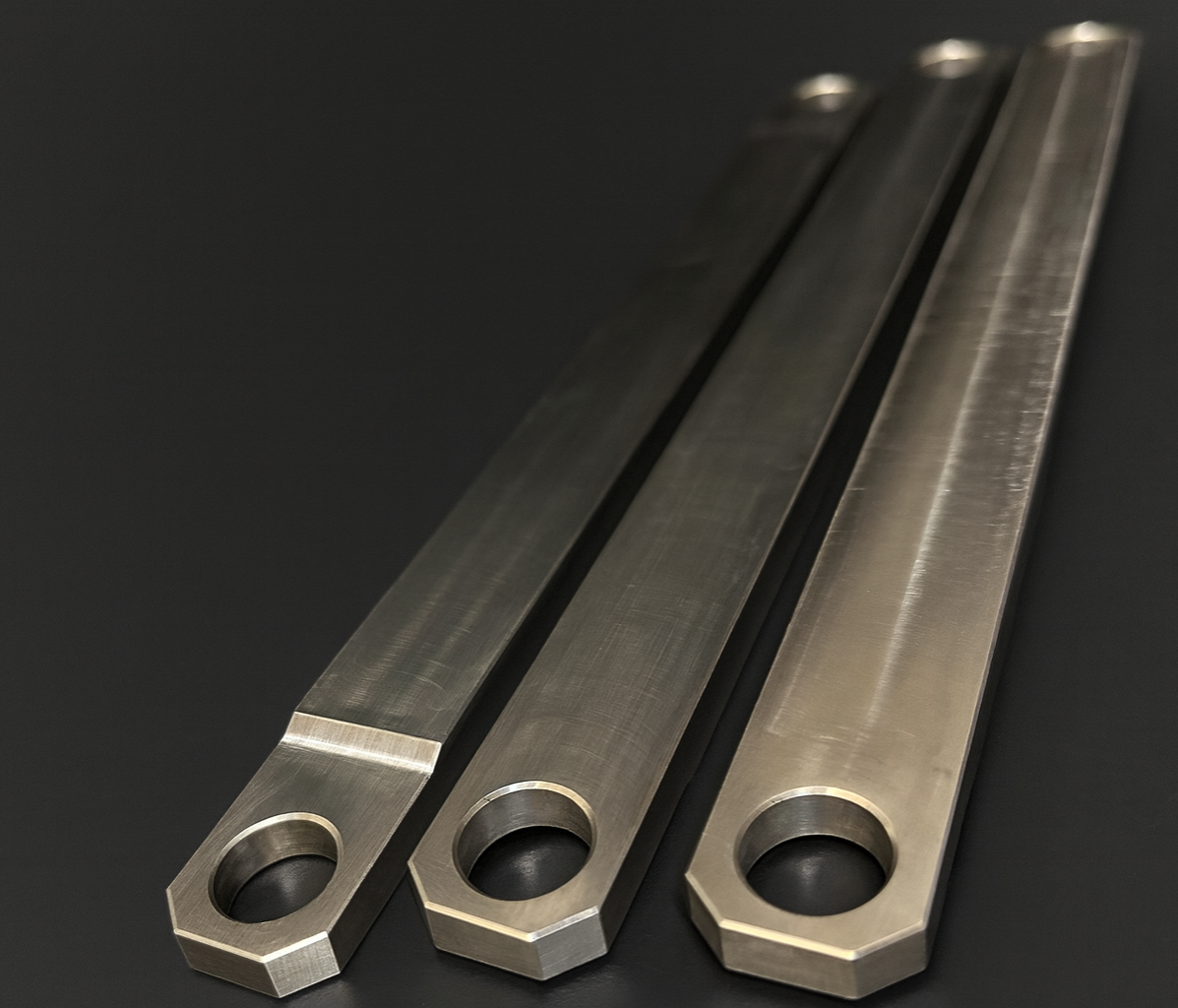

Fasteners

High-End Fasteners

High-End Gears

Specialty Fasteners

Benefit

Passivation is a process to provide a protective coating on metal to make it less reactive to its environment, preventing corrosion.

For stainless steel, the problem is free iron on the metal surface.

Passivation creates a protective oxide layer to shield the metal surface.

Let's Bring Your Project to Life - Free Quote

WHY CHOOSE US FOR YOUR PASSIVATION NEEDS?

Erie Plating Company provides consistent nitric passivation and citric passivation (RoHS) of stainless steel alloys for the purpose of cleaning remnant iron, machining oils, and metal chips and providing a protective coating.

We are skilled in methods and techniques designs to protect your unique parts.

Our customers appreciate the option of citric passivation, an environmentally friendly.

RoHS alternative to nitric passivation.

We are Nadcap accredited for this process.